BlendX

Advanced Quality Control Solution

Achieve consistent, high-quality raw meal, clinker, and cement using Optiverse’s Advanced BlendX Solutions powered by MPC optimization and AI techniques, while extending limestone mine life, reducing carbon footprint, and increasing AFR use for sustainable manufacturing.

Technology

BlendX uses cutting-edge Model Predictive Control (MPC) to optimize cement plant operations with precision. The core features ensure seamless performance and significant operational benefits, aiming to consistently maintain targeted product quality. Key functionalities include

Reference Tracking

Reduces deviations from setpoints for better quality and stability.

Soft Constraint Penalty

Enhances robustness and cuts energy /material costs.

Input Rate-of-Movement (ROM)

Ensures smooth control actions for enhanced stability and longer equipment life.

Targeted Quality Control

Focuses on maintaining key parameters like oxides of Al, Si, and Fe, and derived LSF.

Rawmix Design Support

Facilitates rawmix design based on various fuel combinations for flexible production.

User Interface

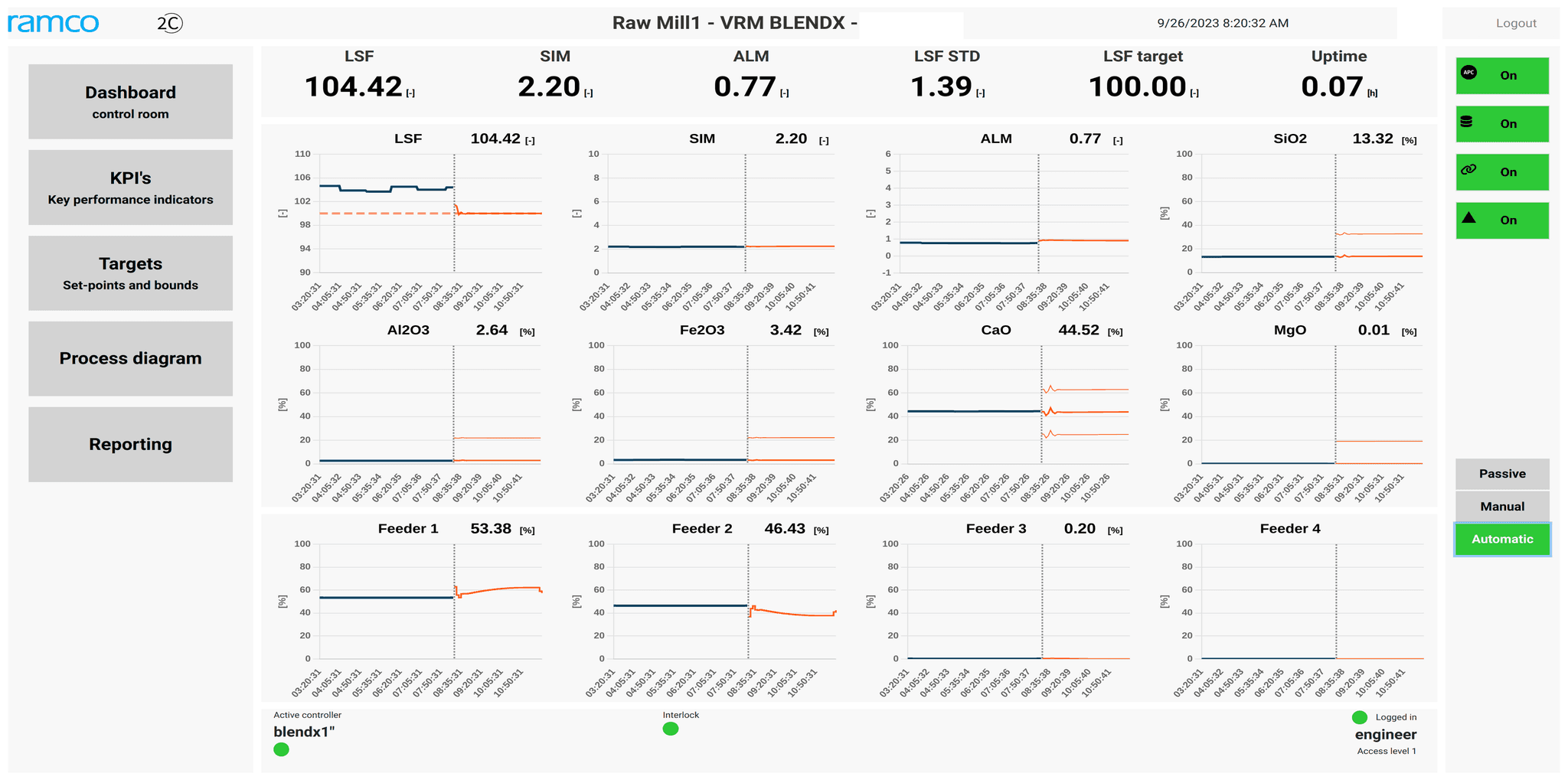

Unmatched Monitoring and User Experience

BlendX is designed to provide seamless user interface for both the operators and Quality Control Specialist. The screens provide easy access to set the required quality target along with Economic factor in place.

Raw grinding

Optimal Blending

BlendX optimizes raw material proportions to ensure desired raw meal quality, balancing efficiency with economic factors.

Advanced Quality Control

Using data from the XRF/Cross Belt analyzer, BlendX enables online quality control to consistently meet raw meal specifications.

Automated Adjustments

The module calculates weigh feeder set points from oxide model predictions, ensuring quality and sending them to the PLC/DCS.

Precise Control

BlendX controls LSF, Silica and Alumina Moduli, and key oxides to ensure optimal raw meal quality.

BlendX also have an add-on feature directly linking Quality to Cost. The BlendX allows the operator to select low priority to raw material of higher cost. This feature will achieve the target quality with minimal usage of raw material which is of higher is cost to reduce overall cost of raw mix.

Cement Grinding

Consistent Quality

Our cement grinding control strategy mirrors that of raw grinding, with a strong focus on maintaining consistent key oxides like SO₃.

Clinker Factor Control

BlendX’s key advantage in cement grinding is its precise control over the clinker factor, especially in Ordinary Portland Cement.

Predictive Quality

BlendX predicts final cement quality by analyzing feed mineralogy and factoring in mill conditions to ensure target specifications are met.

Efficiency Signals

BlendX optimizes the clinker factor and encourages the use of performance enhancers like limestone.

Cost and Environmental Benefits

Reducing the clinker factor lowers power consumption, cuts clinker use, reduces cement production costs, and minimizes CO₂ emissions.

Benefits

Optimise Raw material cost for target quality

Maximize Alternative fuels

Increased Pyro productivity through sustained quality

Lower CO2 Emission with lower clinker factor

Extended Mines life

Use Cases

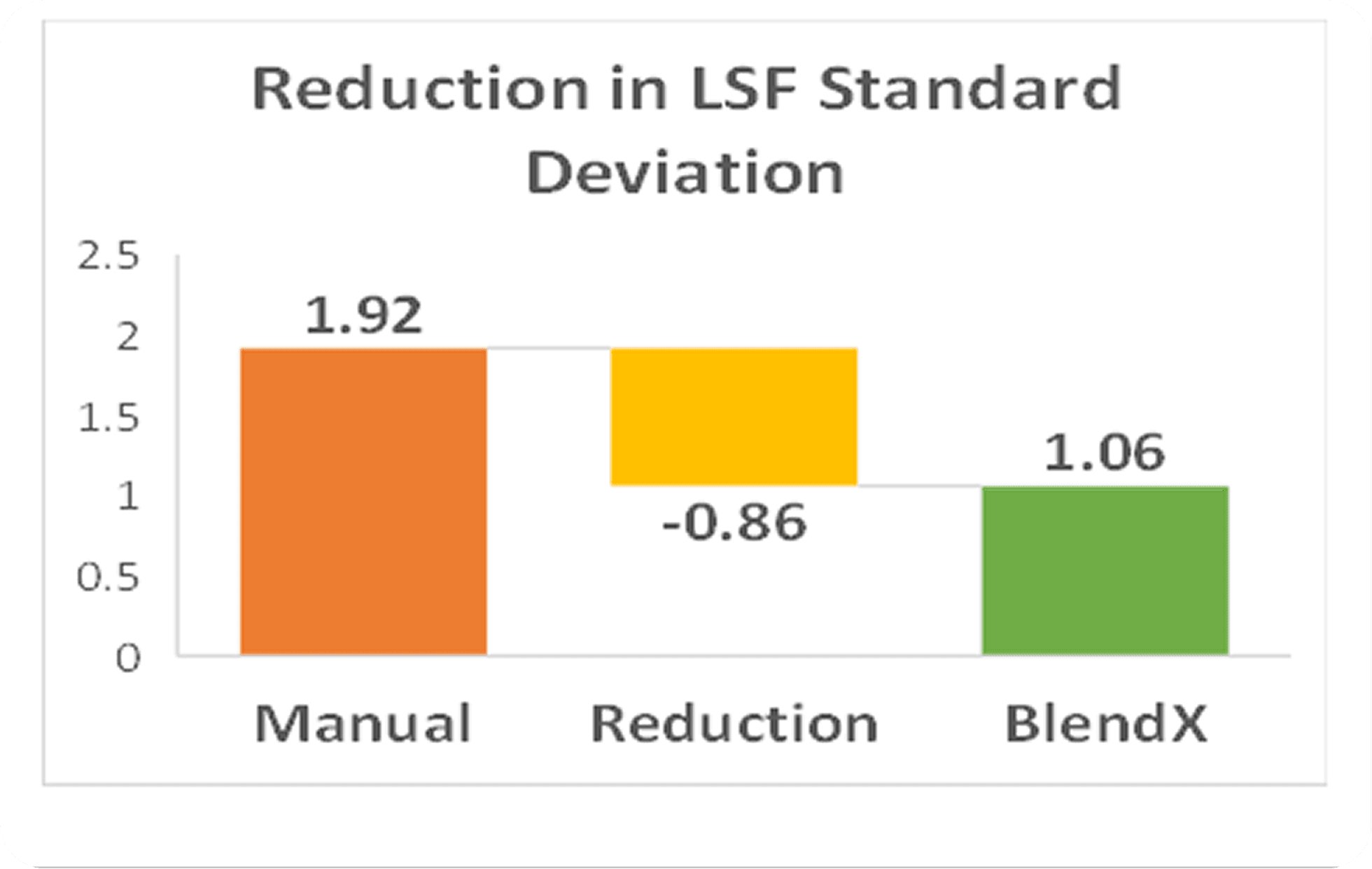

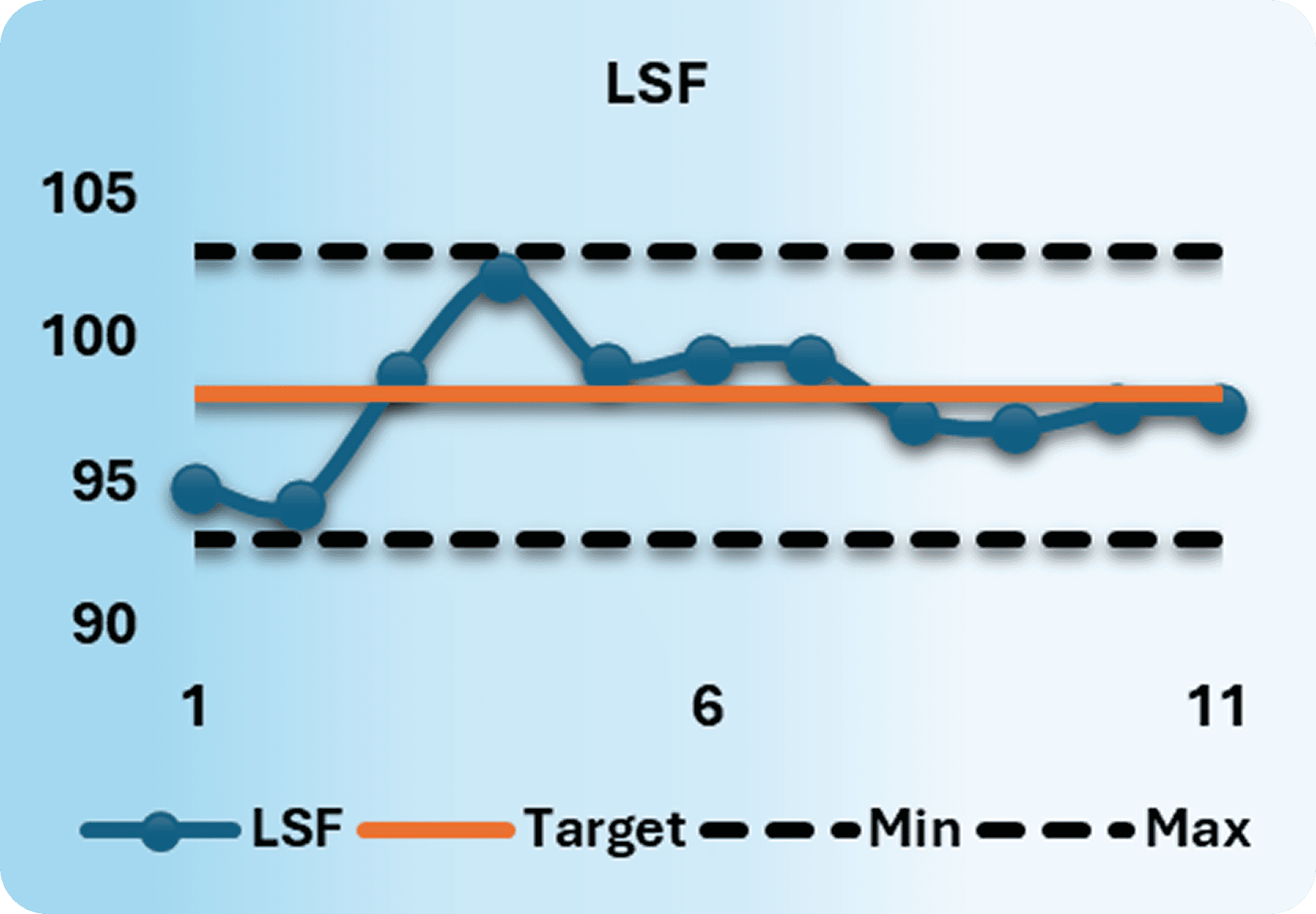

The primary focus for BlendX is reduction in quality variation with minimum of 15% compared to manual operation. Below is a use case in one of the plant. BlendX could reduce the standard deviation variation in LSF from 1.92 to 1.06 which is around 40% reduction. Whereas the other picture depicts how BlendX constantly maintains target LSF

Plant 1

Reduction in standard deviation of LSF through BlendX

Plant 2

Consistent LSF with BlendX

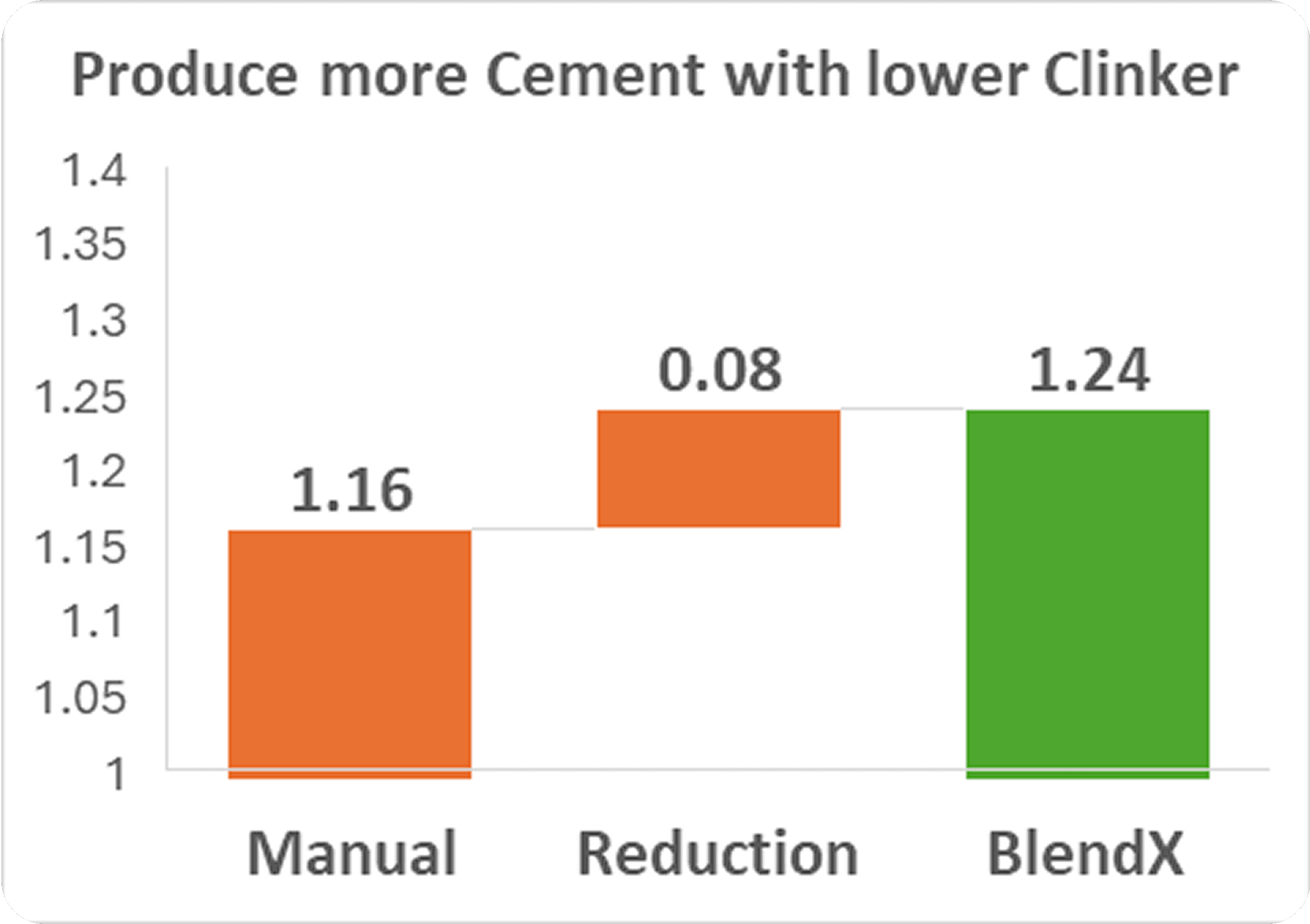

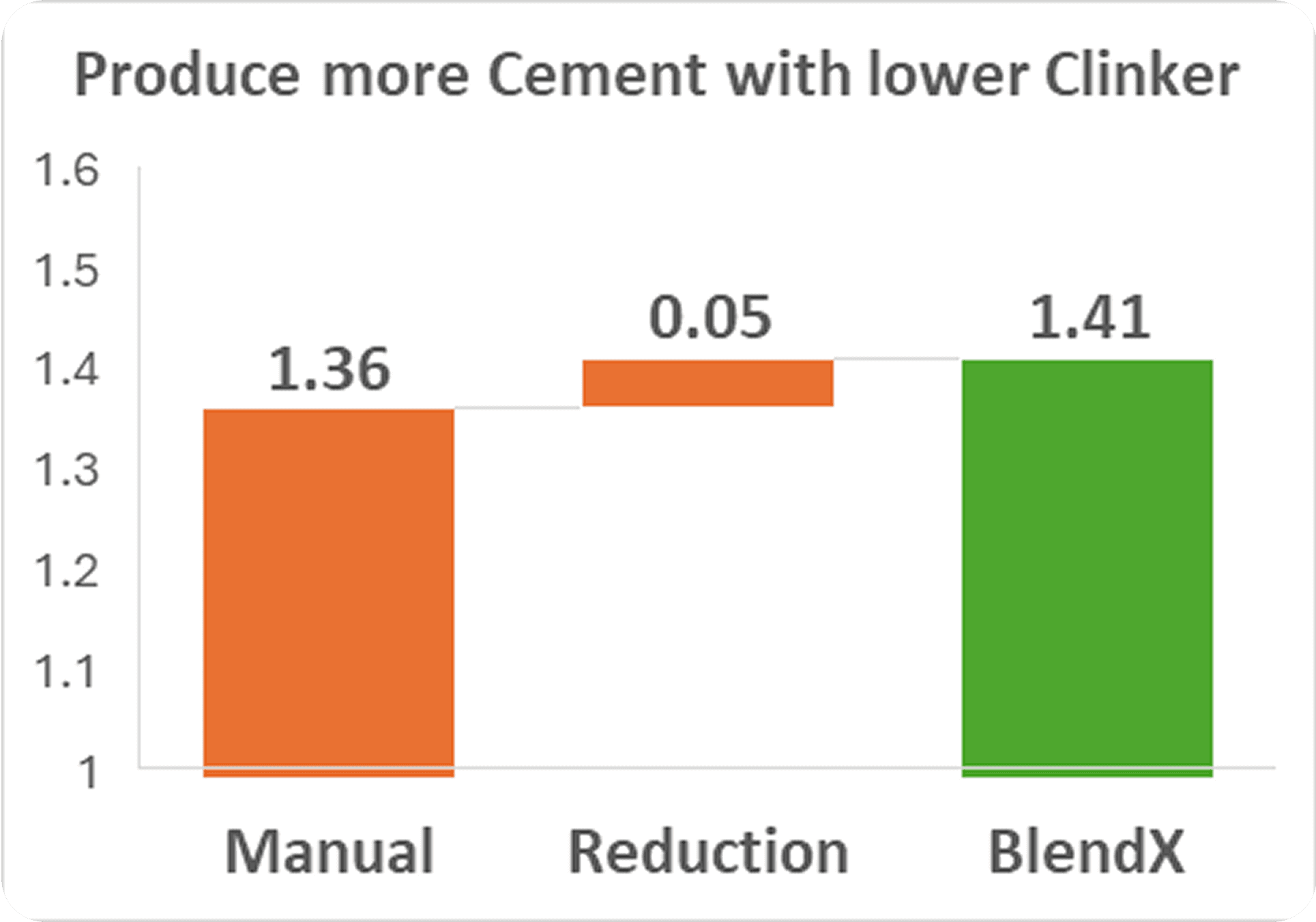

Cement Grinding

Blending in cement production is crucial due to the varying quality of additives and the need to reduce the clinker factor. This reduction is key to lowering CO2 emissions, decreasing specific power consumption, and cutting operating costs. One of Optiverse’s recent installation achieved the below results upon implementing BlendX:

Copyright ©2025 Ramco

A Product By