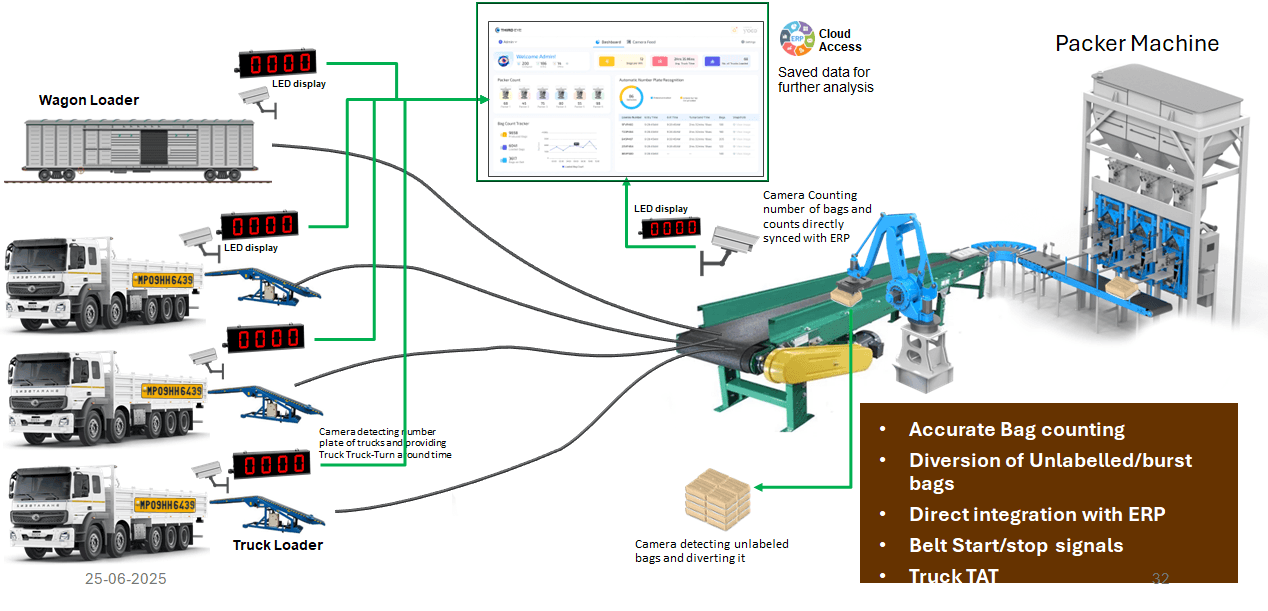

ConveyorVision

Optiverse’s AI-driven ConveyorVision automates cement bag counting and labeling using YOLO-based image analytics, reducing errors, cutting costs, and streamlining packing operations.

Technology

ConveyorVision uses AI-powered YOLO models and HD cameras to track, count, and verify cement bags in real time from packer to truck/wagon. Integrated with ERP, it ensures accuracy across bag types, detects unlabelled or damaged bags, captures truck numbers, and offers dashboards for TAT and equipment efficiency.

User Interface

ConveyorVision loaded with a suite of powerful features designed to provide unparalleled insights and efficiency in packing house operations:

Comprehensive Operational Insights

Gain insights into packing operations to make informed decisions and optimize workflows.

Dynamic Dashboards

Intuitive dashboards display real-time and historical data for quick insights and faster decisions.

Packer and Loader Bag Counts

Accurate bag counting at packer and loader stages ensures every bag is tracked precisely.

Efficiency and Downtime Analysis

Analyze packer & loader efficiency, downtime, & bottle necks to streamline operations & boost productivity.

Turn-Around-Time

Track truck arrivals and departures with number plate recognition for smarter logistics and scheduling.

Seamless ERP Integration

Integrates with ERP to sync bag counts, operations, and efficiency data—boosting business intelligence.

Benefits

Lower operating cost by accurate bag counting

Enhanced customer satisfaction

Accurate data with Seamless ERP integration

Productivity enhancement through proactive decision making

Copyright ©2025 Ramco

A Product By